World Leading Stamping Machines

VeCon Stamping Machines – Higher Density, optimized Coke Quality

During the stamp charging process the coal is compacted outside the coke oven, into a single „briquette“ (coal cake), having almost the same dimensions as the oven chamber.

This coal cake reaches a density of more than 1.1 t/m³ (on wet coal basis with 10% water) – about 30% more than with the loose coal-charge during conventional top charging systems.

The VeCon stamping machine is your guarantee to coke yield and coke quality. It allows a long lifetime, low breakage and higher stamping efficiency.

Highlights:

- Long lifetime (>20 years)

- Very low maintenance

- Customized layout

- Sophisticated friction liners

- Full machine monitoring

- Full automated

- High standard electrical system

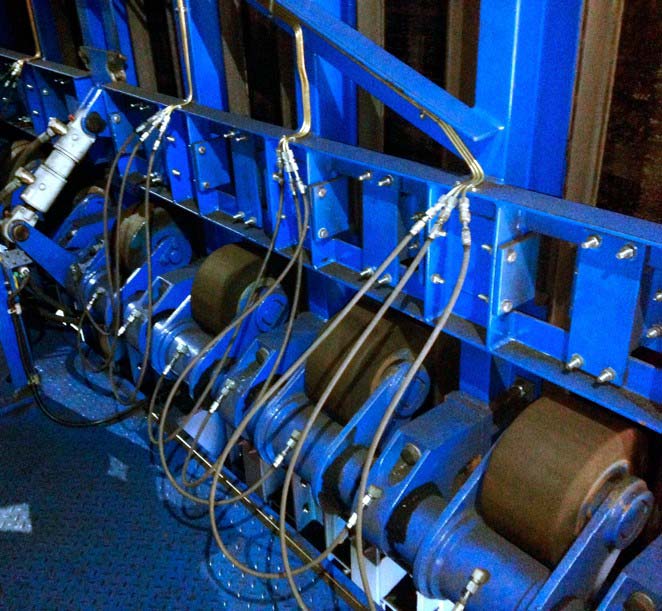

- High standard hydraulic system

Trust our experience

- Total no. of Stamping Machine Projects since Foundation: 52

- Total no. of Stamping System Trains: 104

- Total no. of Stamping Cars (6-fold, 7-fold, 8-fold): 482

- Total no. of Drop Hammers: 3430

WORLD RECORD!

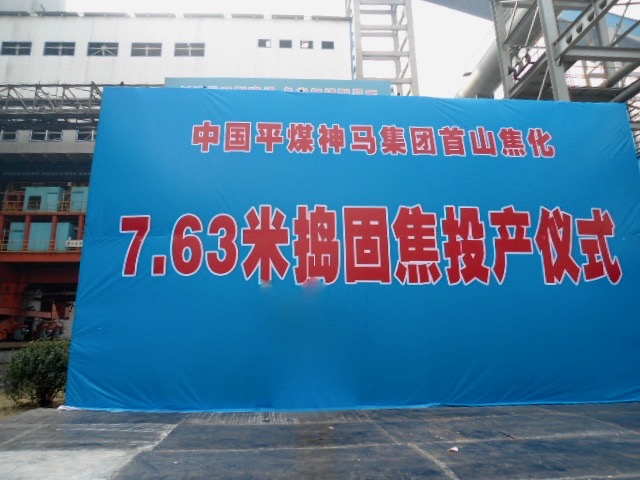

WORLD’S BIGGEST STAMPED COAL CAKE

Key Facts:

- Coal Cake Height: 7100 mm

- Coal Cake Width: 540 mm

- Height-to-Width Ratio > 13

- Coal Cake Length: 17770 mm

- Charging Weight (wet): 75 t

- World’s biggest and heaviest Coal Cake

- World’s biggest Stamping Machine

Background of VeCon Stamping Technology – Historical Overview

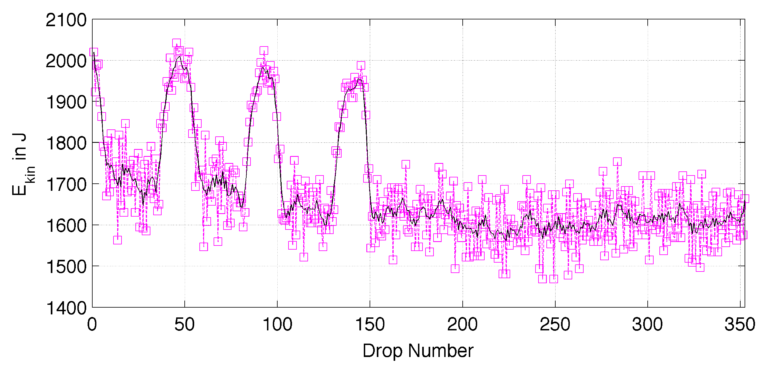

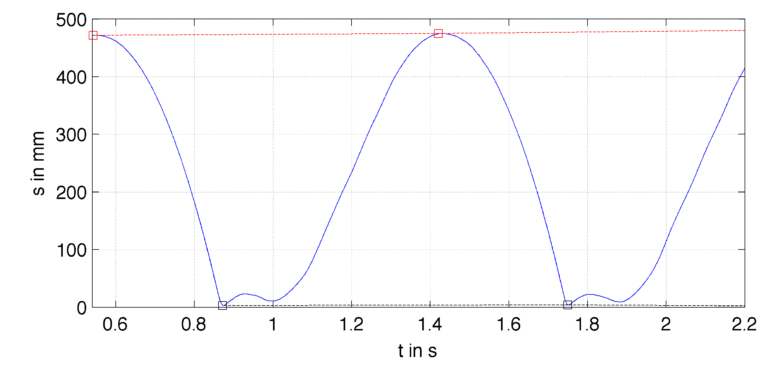

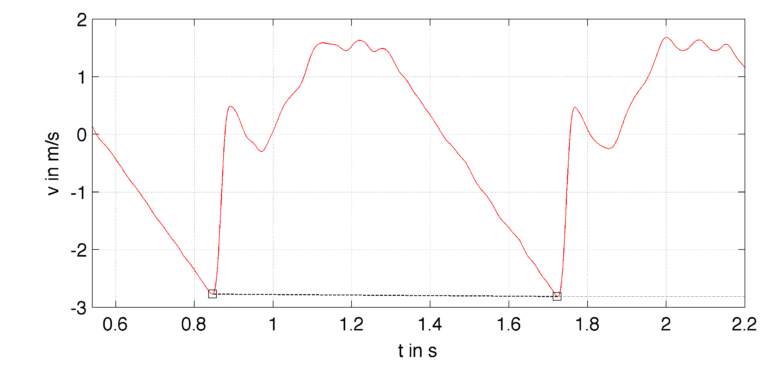

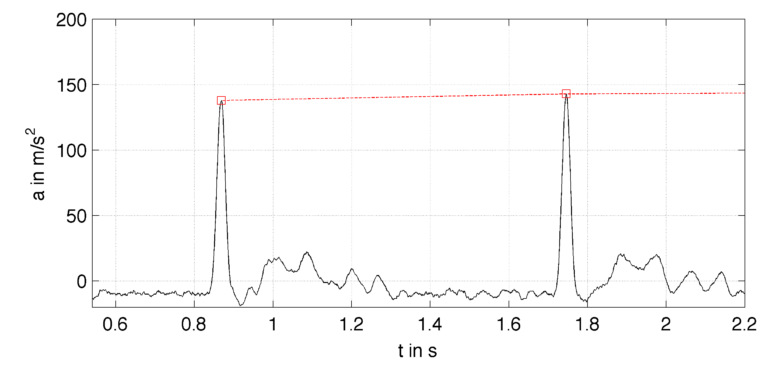

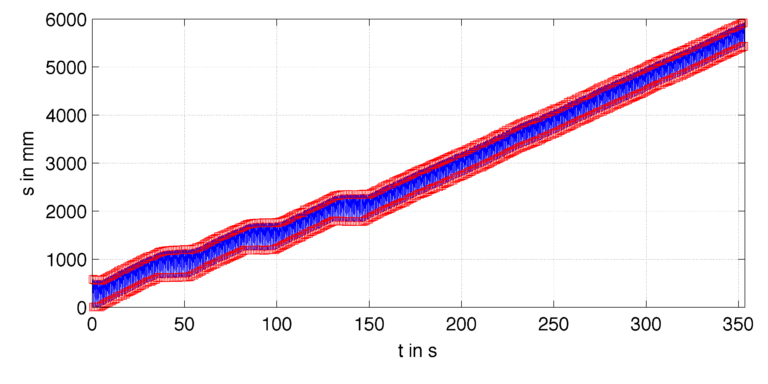

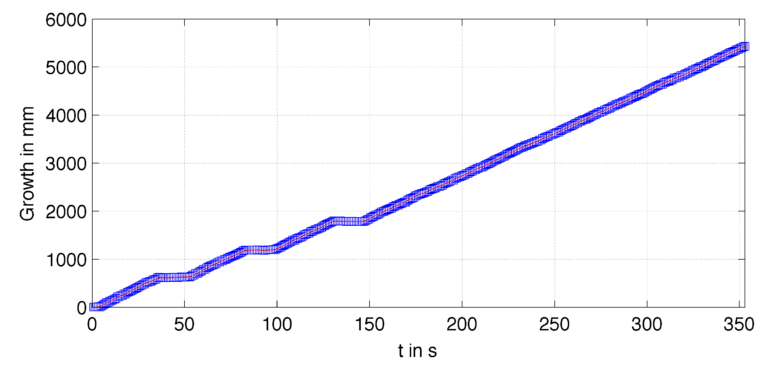

VeCon offers process monitoring for the whole stamping and compaction process based on a wide range of experience. It can either be fixed and continuous process monitoring by installation of permanent measurement equipment or discontinuous process monitoring by equipping the machine with temporary monitoring technology. VeCon has developed own measuring devices and data processing software to guarantee highest efficiency and accuracy. Based on this information, the whole production process in a stamp charging coke plant can be monitored and controlled. With VeCon stamping process monitoring, all important parameters, can be monitored:

- Stamping Hammer Position

- Stamping Hammer Velocity

- Stamping Hammer Acceleration

- Coal Cake Growth

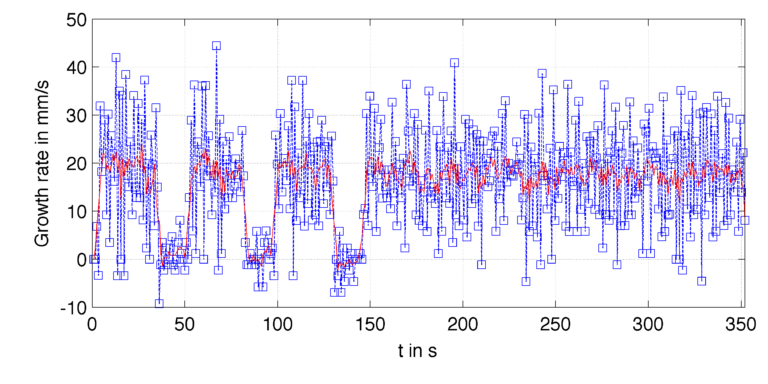

- Coal Cake Growth Rate

- Compaction

- Input Energy into Coal Cake

Stamping Hammer Position (Detail)

Stamping Hammer Speed (Detail)

Stamping Hammer Acceleration (Detail)

Stamping Hammer Position (Full Stamping Process)

Coal Cake Growth (Full Stamping Process)

Coal Cake Growth Rate (Full Stamping Process)

Stamping Input Energy (Full Stamping Process)